- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

- Automated Blast Machines

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

Details

Optional Autotrans Single Axis Lift.

PLC based electrical controls.

Refrigerated cooling system.

The Microsolve has unique proven solvent retention features, such as triple coil reflux cooling, vapour break, 150% freeboard, (with optional auto top-up and solvent monitoring on the larger systems), that provide economic benefits, as well as an effective use of HFE (hydrofluoroether) or HFC (hydrofluorocarbon) solvents.

| Model |

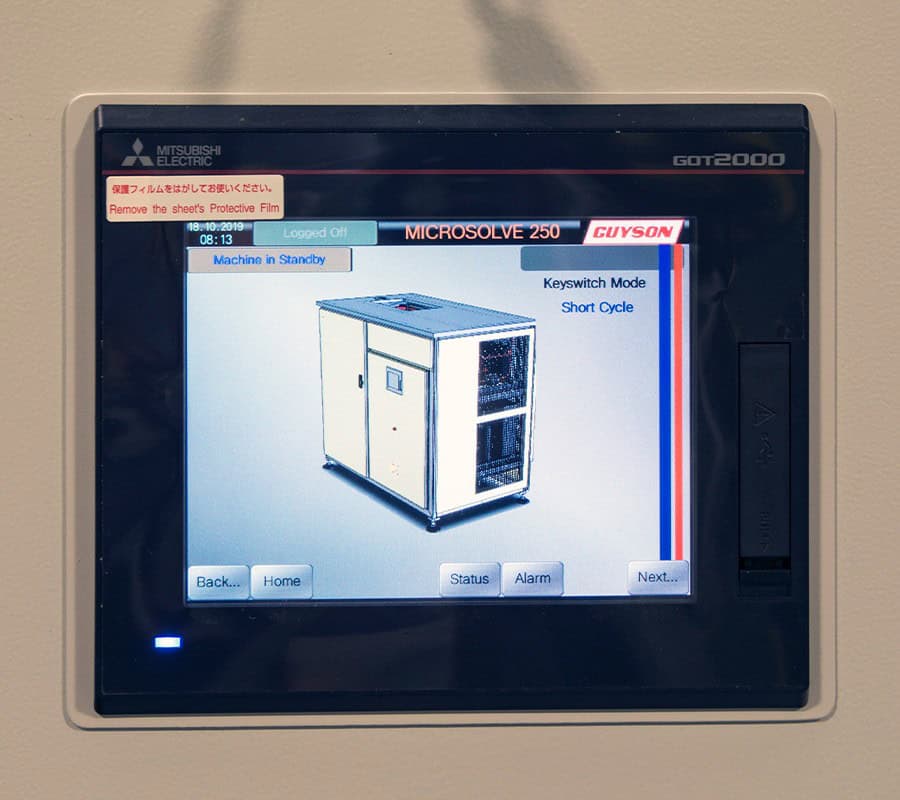

Microsolve 250M |

|---|---|

| Hardware Type |

Automated |

| Machine Type |

Microsolve Ultrasonic Cleaning Systems |

| Internal Tank Dimensions (L x W x D) |

200 x 250 x 250 mm |

| Machine Options |

Autotrans Single-Axis lift |

| Finishing Applications |

Precision Cleaning of Bearings ,Gyro Components ,Medical Components ,Maintenance Cleaning of Pneumatic & Hydraulic Components |

Microsolve Benefits

Discover four standout benefits that come from using Guyson’s Kerry Microsolve Ultrasonic Cleaning Systems for your operations.

Solvent Configuration Options

Guyson’s Microsolve machines are available in both mono & co-solvent configurations.

Efficient Solvent Retention

The Microsolve systems have unique solvent retention features as well as effective use of HFE or HFC solvents.

Cost Effective Operations

The Microsolve range operates with low, predictable solvent usage & therefore efficient running costs.

Increased Automation Capabilities

Guyson’s Microsolve machines are compatible with Autotrans handling systems to increase productivity.

Gallery

360° Product view

Lorem ipsum dolor sit amet consectetur adipiscing elit lobortis, sem quisque duis pretium blandit hac id quam class, facilisis potenti leo senectus aliquam feugiat quis.

Finishing Applications