- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

- Automated Blast Machines

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

As an industry-leading surface finishing company, with an established history in engineering premium blast and ultrasonic equipment to renowned customers within the electronics industry, Guyson understand that safety, quality and meticulous attention to detail is not optional, it’s fundamental.

From low volume operations, such as defluxing select PCBs, to high volume operations including mass hard disk drive component cleaning, Guyson proudly remains the trusted partner for numerous finishing applications, across the electronics industry.

Precision Blasting: Amped-up productivity, controlled quality

Guyson manufacture a wide range of manual, automated and robotically controlled blasting technology, highly suitable for use across the electronics industry.

The specially adapted Formula 1400 CCR, featuring electro static discharge reduction modifications, such as an ionising air curtain, handheld air-assisted ionising gun and extensive earth-grounding straps fitted to all individual items of the entire blast system, performs selective removal of conformal coating from PCBs.

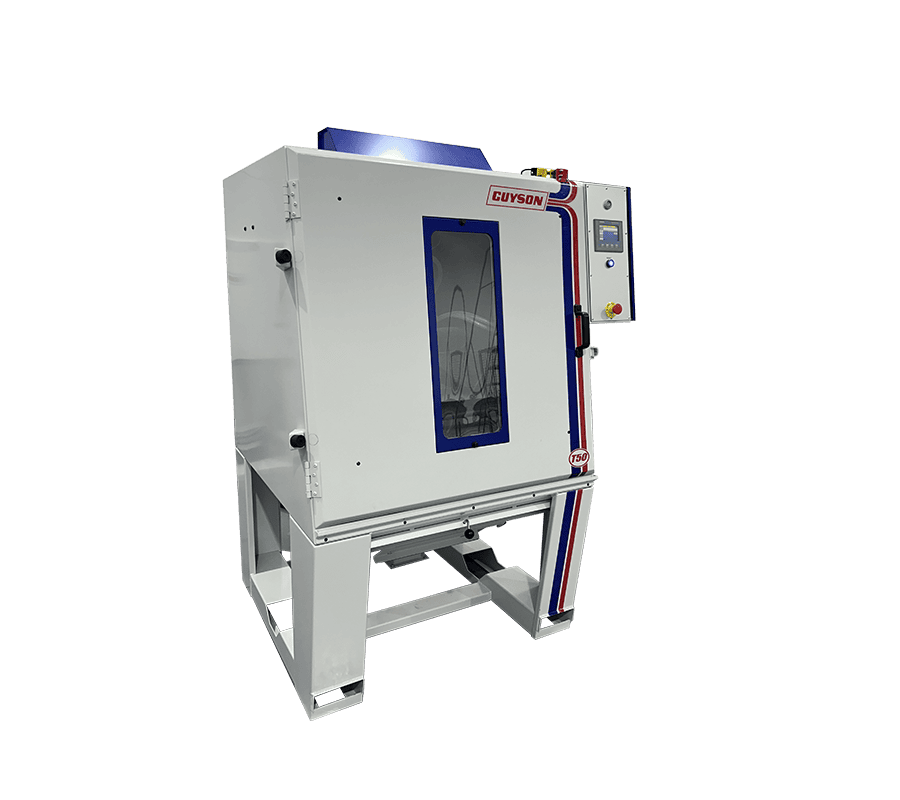

For larger production scales, Guyson’s automated Tumbleblast systems deliver batch-orientated reconditioning of auto-electrics, whilst the Multiblast RXS900 is utilised for reconditioning electric meter boxes.

Ultrasonic Cleaning Technology: High-frequency efficiency, reliable results

From manual small baths to large, automated multi-stage cleaning lines, Guyson produces a variety of ultrasonic cleaning equipment best suited to the needs and requirements of the electronics industry.

Included in Guyson’s manual ultrasonic cleaning solutions are their Ultrasonic Clean-Rinse (UCR) and Clean-Rinse-Dry (CRD) Tanks. The UCR1500 Tanks are notably used for cleaning electrostatic filters, whilst the CRD Tanks perform highly efficient defluxing of PCBs.

Amongst Guyson’s comprehensive selection of automated ultrasonic cleaning systems, are the highly-efficient Microsolve machines, designed to deliver the highest standard of precision cleaning, paramount for the durability of critical electronic components. Guyson’s Microsolve Mono-Solvent Systems undertake a wide range of precision ‘in process’ cleaning routines on numerous fibre optic connectors and interconnectors, whilst the Microsolve Co-Solvent Systems are used for removing no-clean solder flux residues from insulated-gate bipolar transistor (IGBT) power modules, for electric vehicles.

Established for high specification and high volume cleaning applications, Guyson Supercleaners are favoured for working with computer disk drive (HDD) components such as base castings, top covers and head stack assemblies (HSAs) for the world’s leading Hard Disk drive manufacturers. Perfect for high-level cleanroom installations, the Supercleaners provide multi-stage aqueous ultrasonic cleaning, high purity deionised water rinsing, multi-frequency variable power ultrasonics, and hot air drying.

Solvent Specialists: Guyson’s one-stop-shop ultrasonic cleaning solutions

In addition to manufacturing precision cleaning equipment, Guyson supply a range of Inventec solvents compatible with their Microsolve mono and co-solvent cleaning systems, providing customers with a ‘one-stop-shop’ for all their advanced cleaning needs.

Included in Guyson’s Inventec range are their cleaning and cooling fluids, perfect for the electronics industry. Inventec’s hydrocarbon-based cleaning product, Topklean EL 20A, is a specialist solution for flux residue removal, which can be paired in a co-solvent process with Inventec’s solvent cleaning and drying product, Promosolv DR1, mostly used for vapour-phase defluxing and cleaning complex electronic assemblies.

Inventec’s Cooling Thermasolv range consists of high-performing, dielectric cooling fluids developed for safely and efficiently managing heat in electronic and electrical systems. This includes applications such as immersion cooling, direct cold-plate cooling, and dielectric testing, offering strong thermal stability, electrical insulation, recyclability and environmental safety.

To discover in greater detail how Guyson are transforming surface finishing solutions in the electronics industry, contact Guyson today.

‘Try Before You Buy’

Guyson encourages prospective customers to experience first-hand the benefits that their machines can make to your surface finishing operations, by offering free ‘try before you buy’ blasting and ultrasonic cleaning trials, at their state-of-the-art Blast and Wash demonstration facility. To arrange your free component testing, contact Guyson today.