- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

- Automated Blast Machines

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

Details

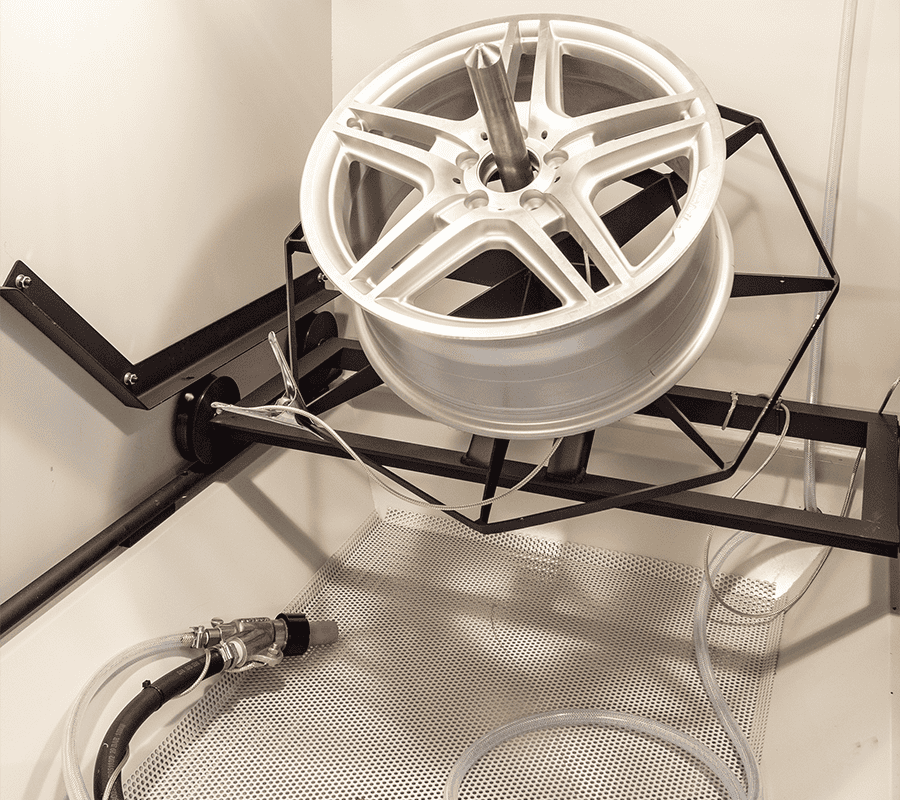

A full-width foot pedal allows the operation of the blast gun with either foot.

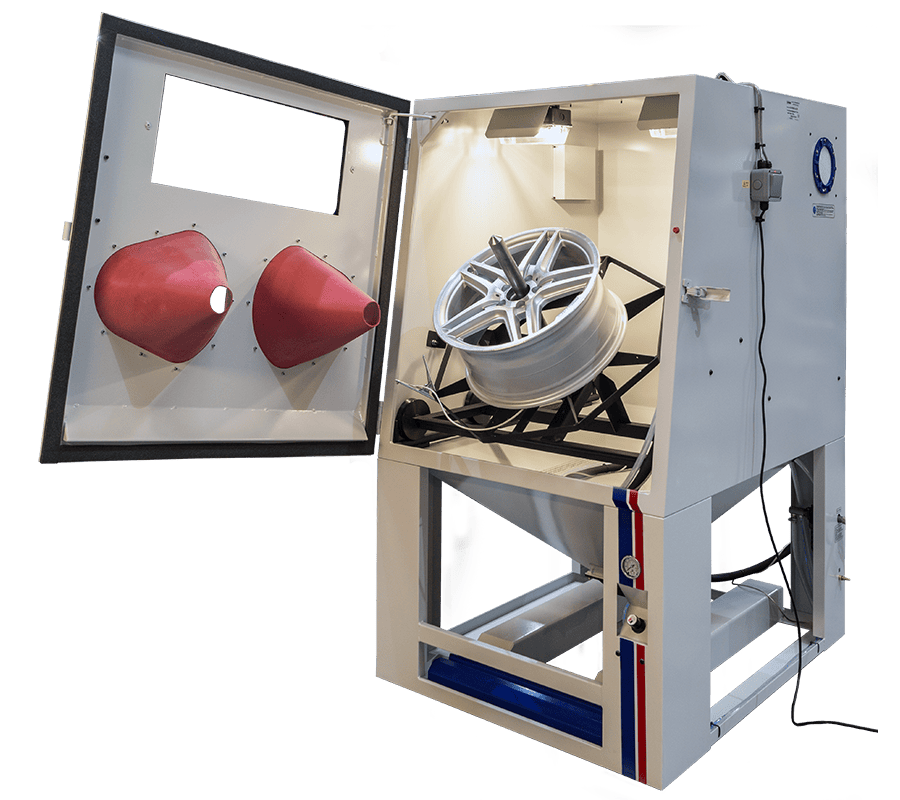

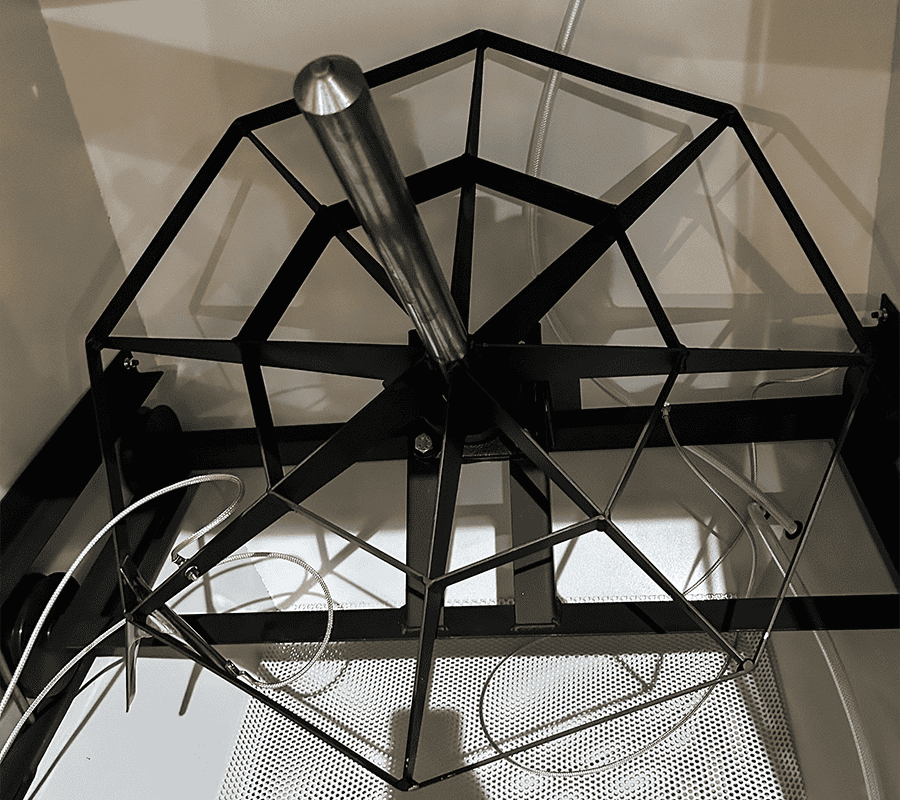

Specifically designed cabinet allows loading and unloading of the wheel without any heavy lifting.

Sealed gauntlet gloves.

This highly efficient manual beadblasting process produces an even finish with easy sweeps across the wheel surface and, unlike traditional disc sanders, it allows both easy penetration of the blast media stream between the spokes as well as very precise localised etching if required.

In addition, the Wheelmaster also provides a fast and even light etching to remove only the chipped lacquer on virtually new wheels, whilst being capable of etching right back to bare metal if required.

| Model |

Wheelmaster |

|---|---|

| Hardware Type |

Manual |

| Machine Type |

Alloy Wheel Blast Machine |

| Overall Cabinet Dimensions (WxDxH) |

990 x 1200 x 1750 mm (990 mm depth version also available) |

| Finishing Application |

Surface Preparation |

Why Choose Guyson's Euroblast® Machines?

Discover four standout features of Guyson’s Euroblast sandblasting equipment.

Flexible Feed Solutions

Guyson’s Euroblast® machines are available in suction and pressure feed options, depending on production requirements.

Labour-Saving Blasting

The Euroblast® manual sandblasting range provides a faster alternative to labour-intensive operations, such as hand deburring, wire brushing and sanding.

Comprehensive Cabinet Choice

The Euroblast® machines come in an extensive range of ‘standard’ sizes, with exceptional component handling designs available to choose from.

Versatile To Applications

Guyson’s industrial sandblasting equipment is ideal for all types of sand, shot, grit or soda blasting and manual shot peening.

Gallery

360° Product view

Lorem ipsum dolor sit amet consectetur adipiscing elit lobortis, sem quisque duis pretium blandit hac id quam class, facilisis potenti leo senectus aliquam feugiat quis.

0%

Finishing Applications