- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

- Automated Blast Machines

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

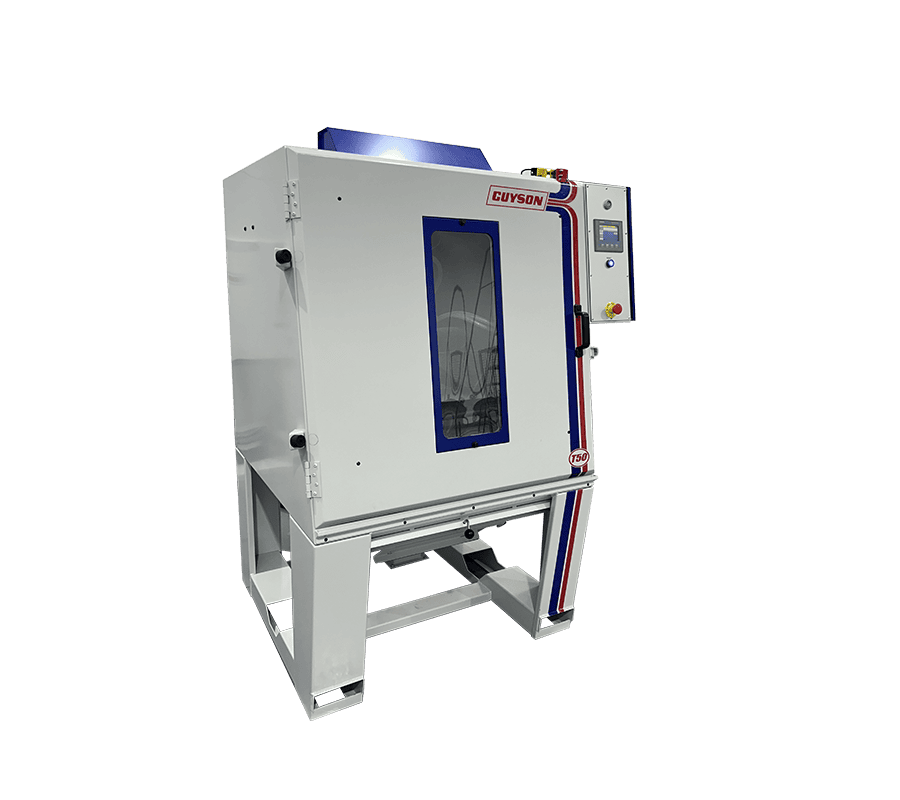

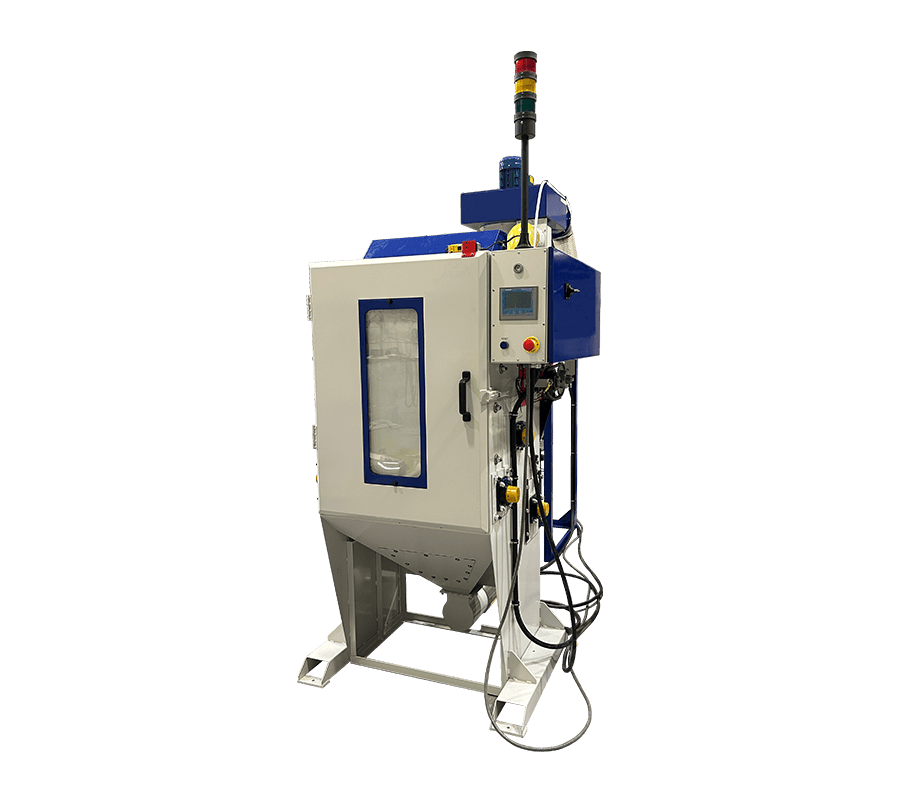

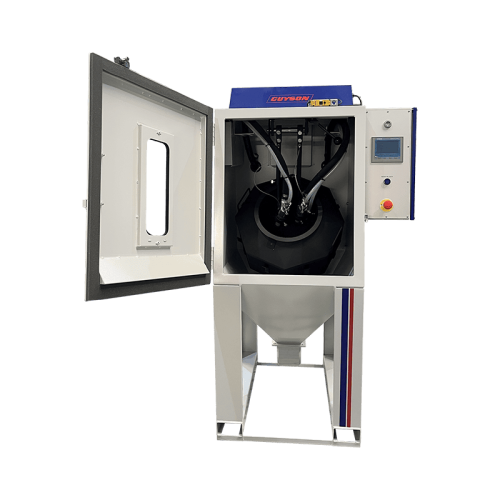

Details

Siemens PLC HMI control panel.

An internal door air wash.

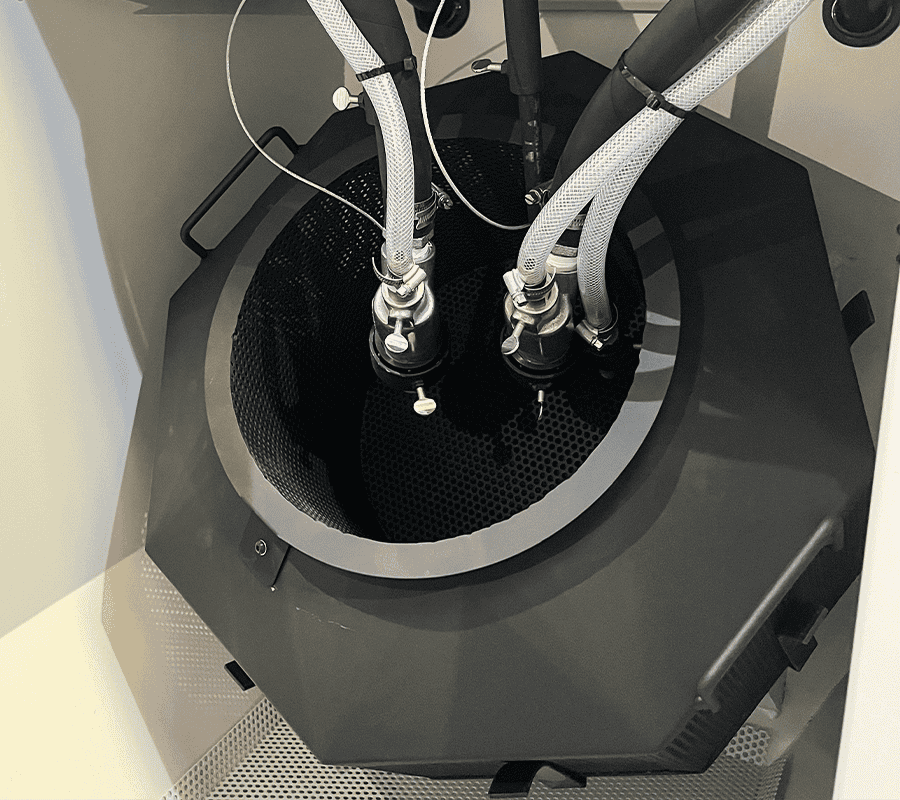

Heavy-duty basket mounting.

Widely adopted across a variety of industries, the T40 Tumbleblast is ideally suited for processing small metal components such as screws, bolts, nuts, washers, circlips, and aerospace fasteners.

The T40 comes with a one or two blast gun option for customers, depending on the blast application requirements.

| Model |

T40 |

|---|---|

| Hardware Type |

Automated |

| Machine Type |

Small Parts Batch Blasting (Tumbleblast) |

| Max Load |

35 kg |

| Max Volume |

15 L |

| Finishing Application |

Cosmetic Finishing ,Deburring ,Surface Preparation |

Why Choose Guyson's Tumbleblast Machines?

Discover four standout features of Guyson’s automated tumbleblasting machines.

Efficient

Guyson’s small parts batch tumbleblasting machines deliver fast cycle times.

Repeatable

These automated systems ensure repeatable process quality every time.

Versatile

The Tumbleblast range is versatile to meet the needs of various industries and applications.

Cost Effective

Guyson’s innovative machines offer high quality, cost effective blast finishing for batch processing.

Downloads

Gallery

360° Product view

Lorem ipsum dolor sit amet consectetur adipiscing elit lobortis, sem quisque duis pretium blandit hac id quam class, facilisis potenti leo senectus aliquam feugiat quis.

0%