- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

- Automated Blast Machines

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

For over 80 years, Guyson’s surface finishing solutions have set the standard for performance in the highly demanding aerospace sector. Guyson understand the importance of consistency and reliability, ensuring every system delivers the exceptional results the industry expects.

Guyson’s portfolio of premier blast and ultrasonic cleaning systems supports a wide range of aerospace applications, including but not limited to:

Guyson’s Blasting Capabilities: Engineered Perfection and Reliability

From traditional manual blast systems to bespoke automated and robotically controlled solutions, Guyson’s blast technology is engineered for versatility across aerospace applications.

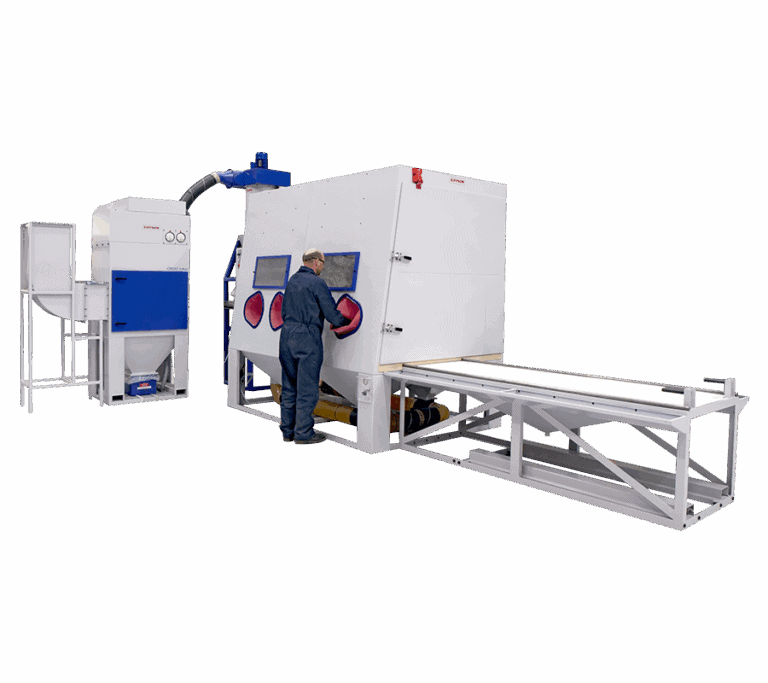

One notable example is the Euroblast 2.5 Metre Side Loading PF Blast System, our largest manual blast system. Designed for large components, it features a side loader for efficient loading and unloading. A common aerospace application is the etching of large circular aluminium rings prior to bonding.

For more complex applications requiring high precision and scalability, Guyson offers automated and robotic blast systems. Operated via intuitive PLC/HMI screens, these systems provide real-time process customisation and parameter control, ensuring repeatable, high-quality results.

A key aerospace application is turbine blade processing reconditioning and shot peening.

- For reconditioning, the Multiblast RXS900 is a proven solution. With multiple spindle and turntable configuration options, it combines increased throughput with the accuracy of automation.

- For shot peening, the RB10 Robotic Blast delivers unmatched consistency. Meeting AMS2432 standards, the RB10 ensures turbine blade roots are shot peened with precision, meeting the most stringent aerospace requirements.

Guyson’s Ultrasonic Cleaning Technology: Transformative Precision

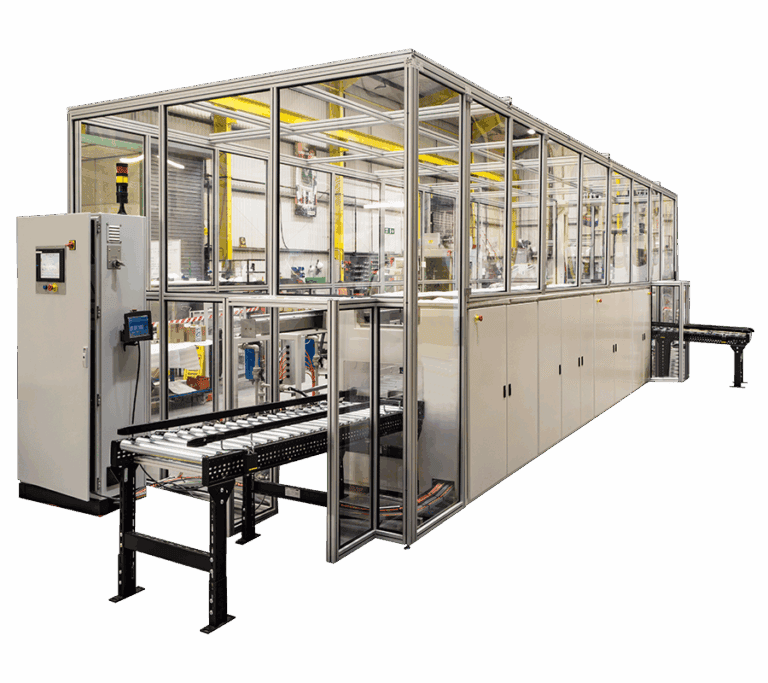

Guyson’s ultrasonic cleaning portfolio ranges from small manual baths to advanced Microsolve systems, up to fully automated multi-stage cleaning lines designed for high throughput aerospace applications.

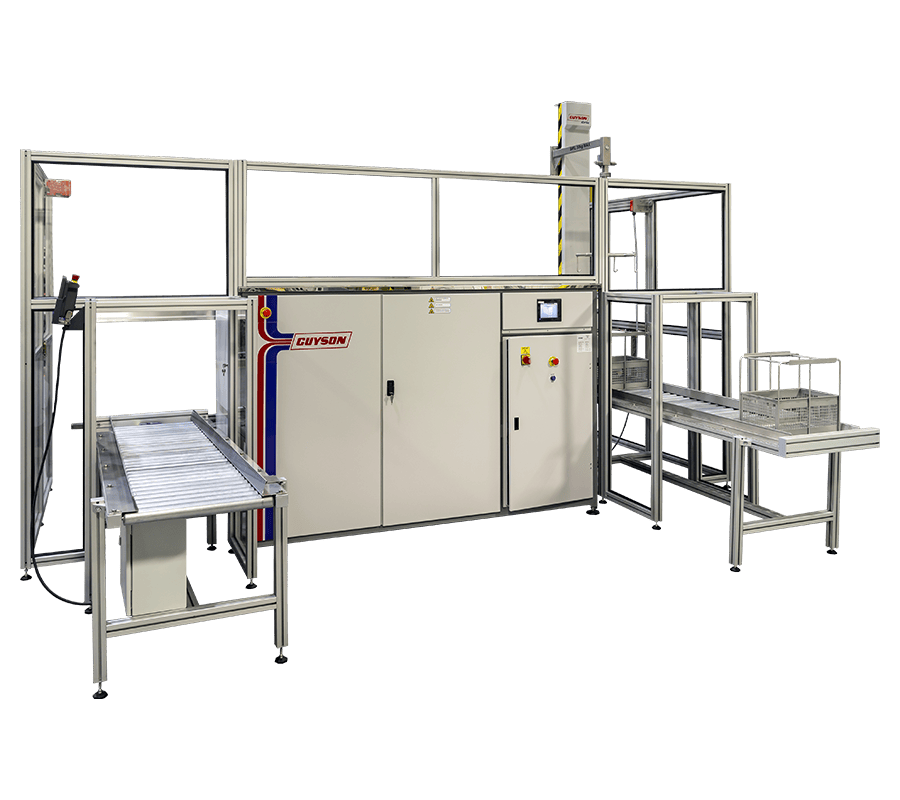

For processes demanding automation and reliability, the Microsolve Mono and Co-Solvent systems are the standout choice. These systems integrate ultrasonic cleaning, ultrasonic rinsing, vapour rinsing and freeboard drying in a single automated unit. Aerospace customers trust the Microsolve for cleaning aircraft guidance systems, reconditioned gearbox components, hydraulic systems and actuators.

For heavy duty applications, the Microclean 450 delivers exceptional results. Frequently used to remove cutting fluids from aerospace propellor casings, the Microclean system comes with four modular stages as standard: heated ultrasonic clean, rinse, rinse and warm air dry. Its modular design allows additional stages to be installed for specialised requirements.

Wet Blast Specialists: Guyson Corporation USA

Our United States counterpart, Guyson Corporation USA, specialises in wet blasting systems for aerospace. Wet blasting is highly effective for cleaning and surface preparation, including paint and rust removal, degreasing and improving adhesion before coating.

One example includes a custom system capable of pumping flows of up to 200 gallons per minute, engineered to meet the industries strictest performance demands.

Find Out More

To discover in greater detail how Guyson’s innovative blasting and ultrasonic cleaning solutions can transform your aerospace processes, contact the Guyson team today.

Guyson’s ‘Try Before You Buy’ Service

Guyson encourages prospective customers to experience first-hand the benefits that their machines can make to your surface finishing operations, by offering free ‘try before you buy’ blasting and ultrasonic cleaning trials, at Guyson’s state-of-the-art Blast and Wash demonstration facility.

To arrange your free component testing, contact Guyson’s team today.