- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

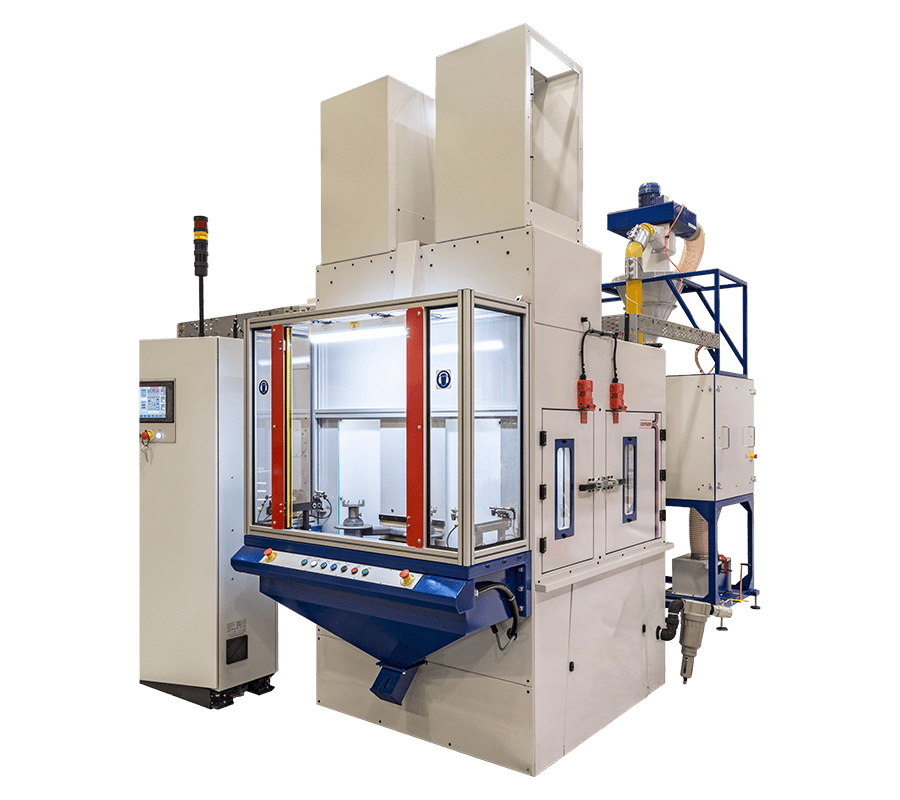

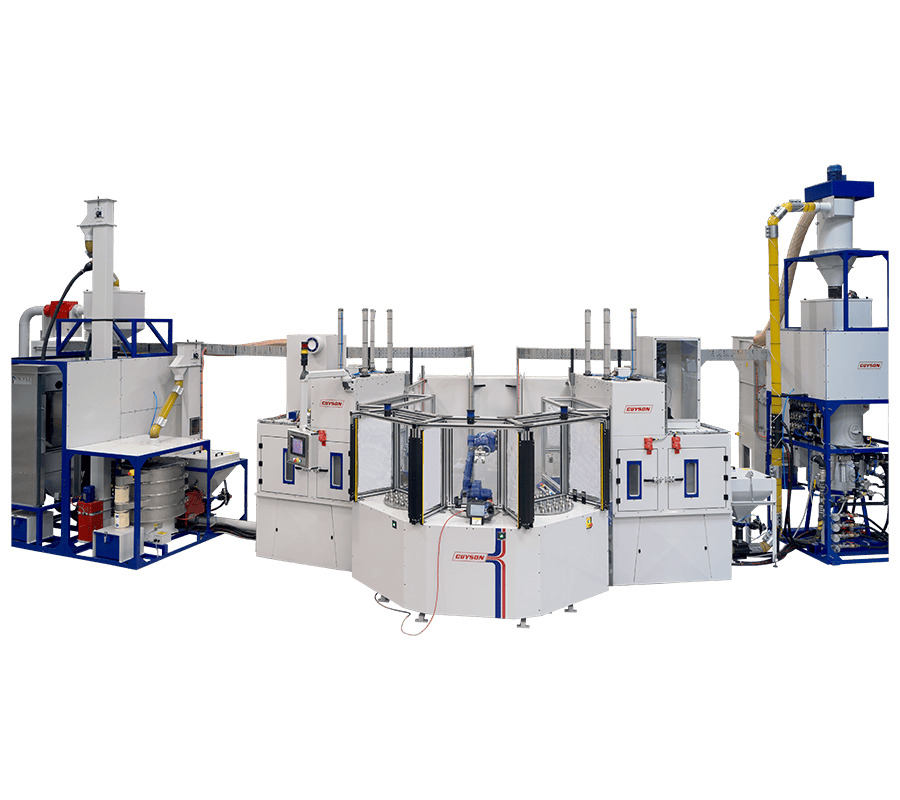

- Automated Blast Machines

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

Details

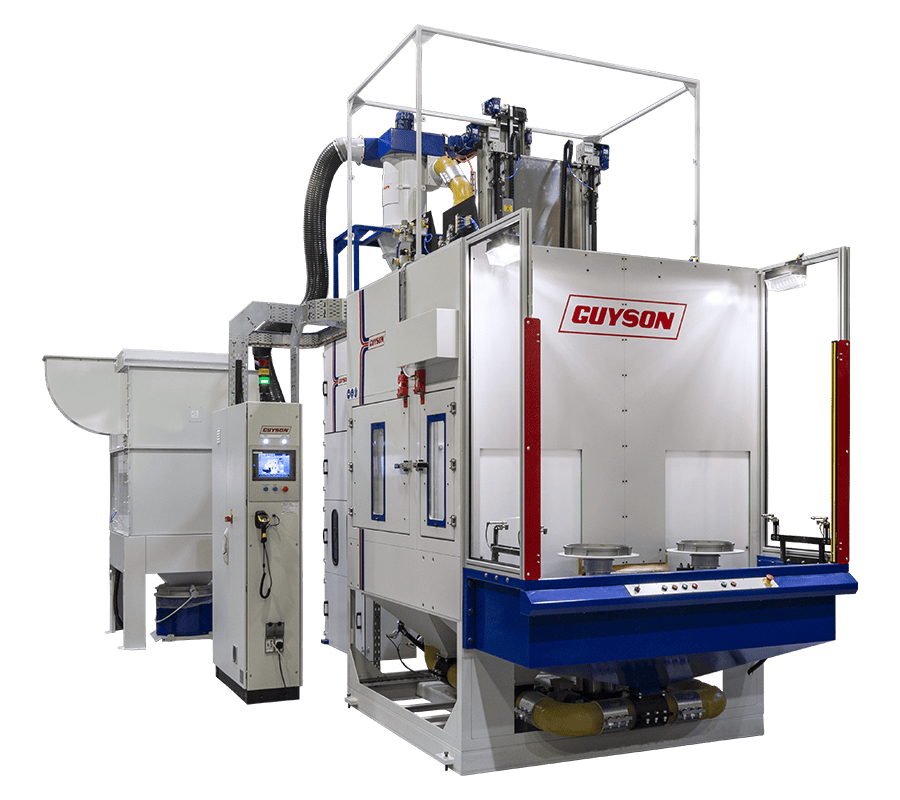

6 x Model 900 Blast Guns complete with electrical solenoid switches.

HMI/PLC control systems with graphic interface.

Blast guns are mounted on adjustable mounting blocks, to achieve optimum coverage of the component.

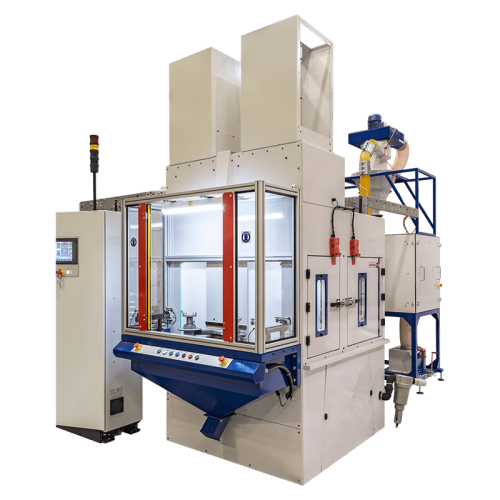

Blast guns can be secured to a vertical traversing gun drive, for taller components.

Components can be either manually, pick and place or robotically loaded and unloaded depending on volumes, handling complexity and subsequent operations.

A suction or pressure feed media delivery system, media separator and dust extraction system make up a complete installation and these items are specified to match each specific application.

A separate, dedicated air wash station ensure parts are clean and ready for the next stage of production.

| Model |

RXS900 |

|---|---|

| Hardware Type |

Automated |

| Machine Type |

Rotary Indexing Blast Systems |

| Max Component Weight |

10 kg |

| Minimum Cycle Time |

6 – 10 secs |

| Finishing Application |

Cosmetic Finishing ,Deburring ,Shot Peening ,Surface Preparation |

Why Choose Guyson's RXS Machines?

Discover four standout features of Guyson’s rotary indexing blasting systems.

Reliable Results

Guyson’s highly versatile RXS systems deliver continuous, selective or overall surface finishing of components produced in volume.

Highly Accurate

The RXS range is designed & engineered to ensure a high level of process & machine control for accurate and consistent results.

Additional Features Available

Components can be fitted with special fixtures & dedicated holding facilities, to accommodate diverse component shapes.

Increased Productivity

Guyson’s RXS range have been developed over decades, to provide a safe, automated solution for higher volumes and increased productivity.

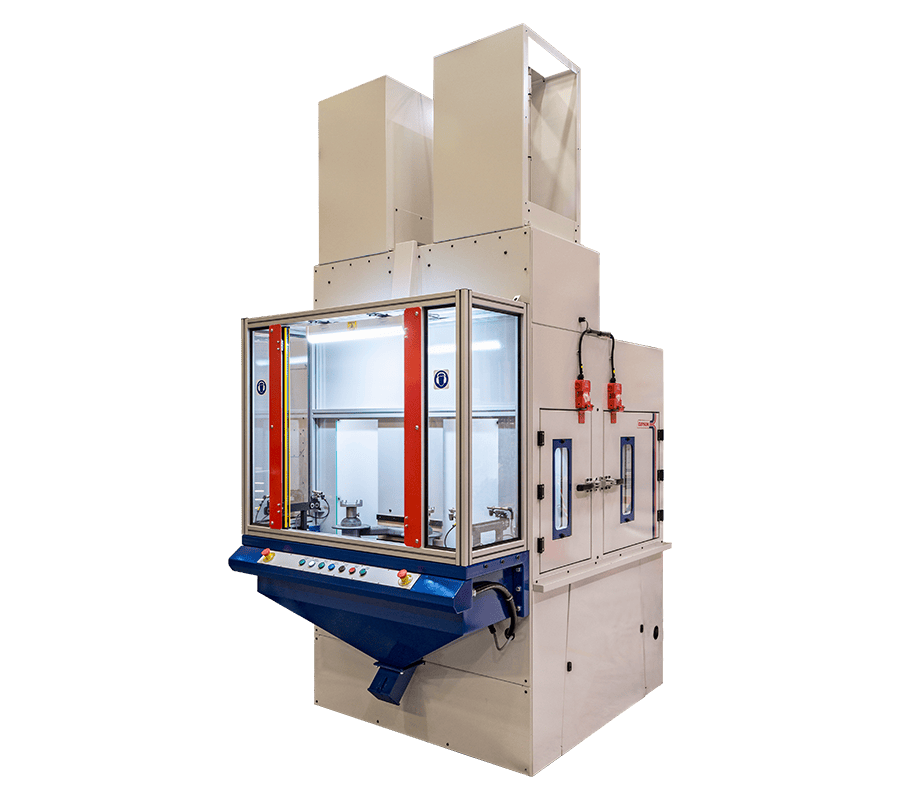

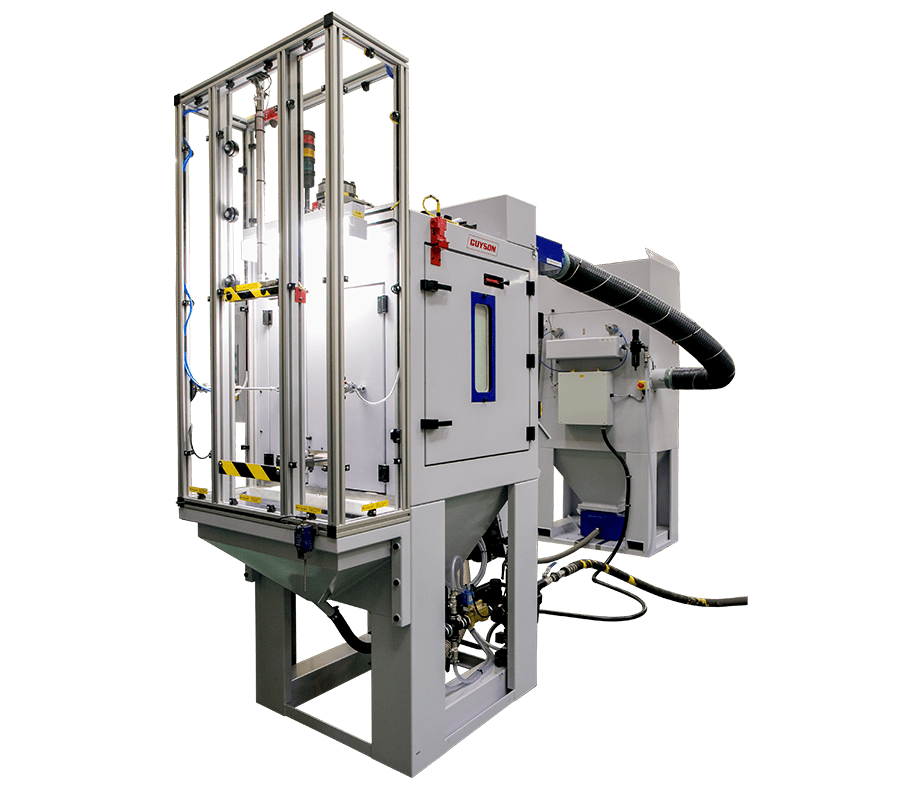

Gallery

Downloads

360° Product view

Lorem ipsum dolor sit amet consectetur adipiscing elit lobortis, sem quisque duis pretium blandit hac id quam class, facilisis potenti leo senectus aliquam feugiat quis.

0%

Finishing Applications