- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

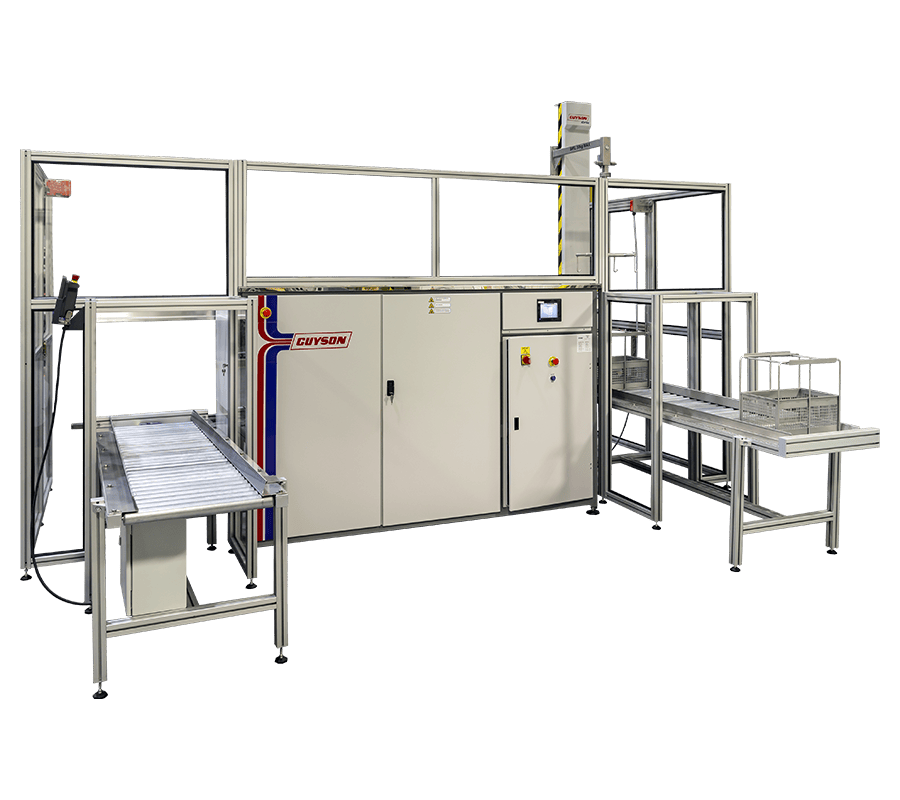

- Automated Blast Machines

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

As an industry-leading surface finishing company, with an established history in engineering premium blast and ultrasonic equipment to renowned customers within the automotive industry, Guyson understand that safety, quality and meticulous attention to detail is not optional, it’s fundamental.

From garage maintenance and classic car parts restoration, to Tier 1 OEM manufacturers and Formula 1 race teams, Guyson proudly remains the trusted partner, for numerous finishing applications, across the automotive industry.

Guyson’s Blasting Capabilities: Accelerated throughput, repeatable quality

Guyson manufacture a wide range of manual, automated and robotically controlled blasting technology, highly suitable for use across the automotive industry.

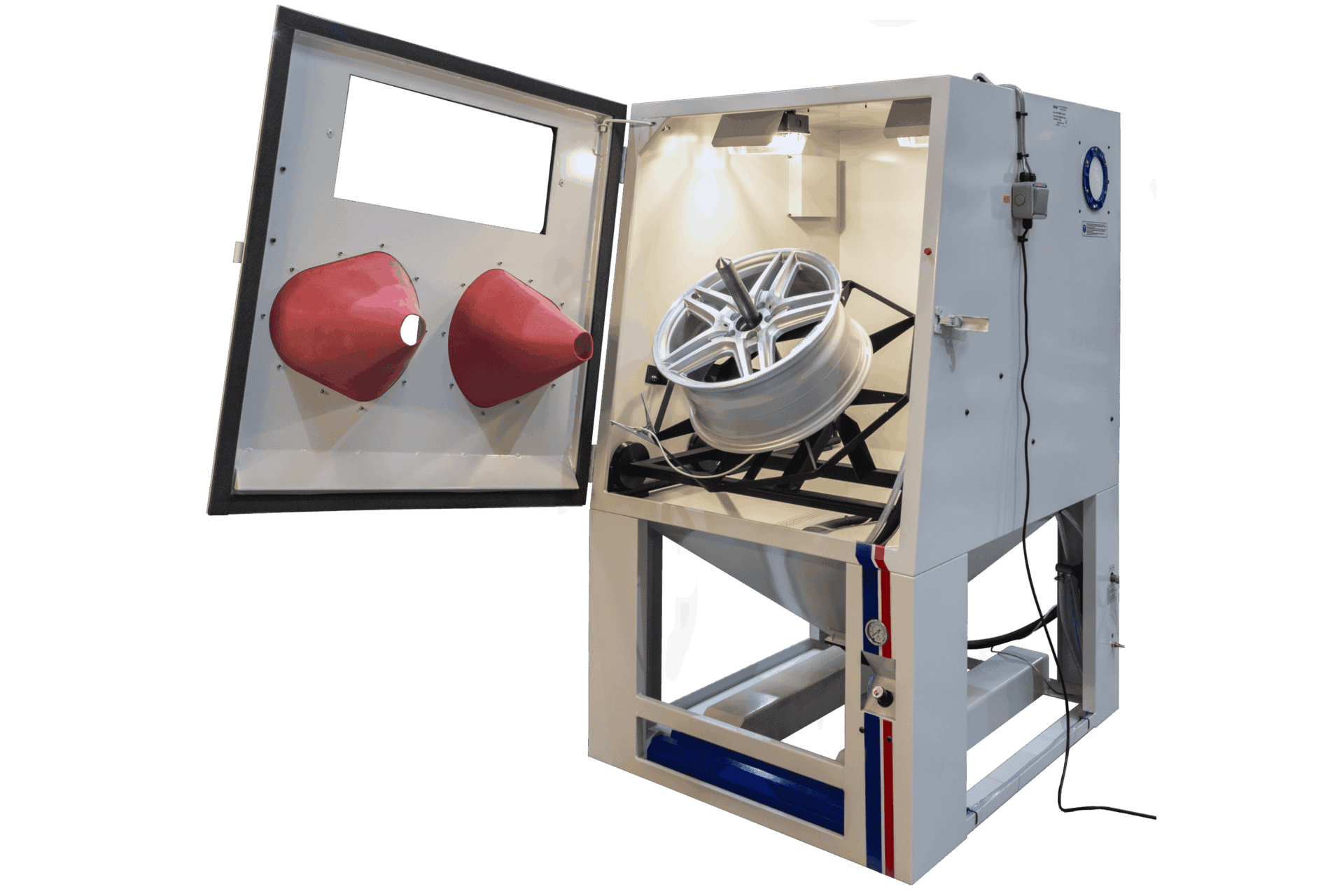

A standout manual blasting system within Guyson’s comprehensive range, is the Wheelmaster, specially designed for blast etching alloy wheels. Built with specific handling features to enable operators to safely load and unload each wheel, the manual beadblasting machine helps operators to produce an even finish with easy sweeps across the wheel surface. Unlike traditional disc sanders, the Wheelmaster allows both easy penetration of the blast media stream between the spokes as well as very precise localised etching.

For more complex geometries, as well as larger components and production scales, Guyson’s automated and robotically controlled blasting technology delivers real-time customisation, multi-axis coverage, pin-point control of process parameters, and flexible component or blast gun manipulation. All engineered to improve adhesion, extend component life, and enhance overall product performance.

Some examples include Guyson’s Multiblast RSB - Rotary Spindle & Table Blast Systems, which have been used within the automotive industry for shot peening con rods. These cutting-edge machines are built with flexibility for either fixed or transversing guns (horizontal or vertical inverter controlled driven gun drive options), and a spindle or turntable fixture, to suit almost any shot blasting or peening process. Whilst the Multiblast RXS900 - Rotary Indexing Blast Systems engineered to allow continuous, selective or overall surface treatment of individual components, produced in volume, have been utilised by the automotive industry for removing feather burrs left on blade tips of turbocharger wheels, after grinding.

Guyson’s Ultrasonic Cleaning technology: Shifting gears in automotive precision cleaning

From manual small baths to large, automated multi-stage cleaning lines, Guyson produces a variety of ultrasonic cleaning equipment best suited to the needs and requirements of the automotive industry.

Guyson’s range of Ultrasonic GUK Benchtop Baths are the safe, fast and effective choice by many for ultrasonic cleaning carburettors and diesel injectors. Given their compact design and versatile range of sizes, the GUK Benchtop Baths are the perfect addition to any garage and maintenance workshop.

For greater component volumes, Guyson’s manual KS Tanks, microprocessor-controlled for precise results, and UCR Ultrasonic Cleaning Tanks, designed to deliver an ultrasonic clean and rinse process, are utilised for removing oils and greases, as well as providing outstanding ultrasonic cleaning results for brake, clutch and gear assembly components.

Guyson’s four-stage Microsolve Co-Solvent System, which seamlessly integrates ultrasonic cleaning, ultrasonic rinsing, vapour rinsing and freeboard drying is the go-to choice, in the automotive industry, for heavy contamination removal. Guyson’s Microsolve Co-Solvent utilises a combination of HFE or HFO, and petroleum distillate-based solvating agent to enhance cleaning operations for more complex requirements. Notably, this highly-efficient system has been implemented for the precision cleaning of F1 aluminium and titanium engine and gearbox components.

To discover in greater detail how Guyson’s innovative blasting and ultrasonic cleaning solutions can transform your automotive processes, contact the Guyson team today.

Guyson’s ‘Try Before You Buy’ Services

Guyson encourages prospective customers to experience first-hand the benefits that their machines can make to your surface finishing operations, by offering free ‘try before you buy’ blasting and ultrasonic cleaning trials, at Guyson’s state-of-the-art Blast and Wash demonstration facility. To arrange your free component testing, contact Guyson’s team today.