- Flexible Hose Assemblies

- Hansen Quick-Release Couplings

-

Hansen Couplings

- Hansen HK series self-sealing couplings

- Hansen ST series straight-through couplings

- Hansen MLDB series dry-break couplings for fluid transfer (stainless steel)

- Hansen ADB series dry-break couplings for fluid transfer (aluminium)

- Hansen MLFF series ISO 16028 dry-break couplings (stainless steel)

- Hansen FF series ISO 16028 dry-break couplings

-

Danfoss Aeroquip

- Danfoss Aeroquip 5400 series low air inclusion refrigerant couplings

- Danfoss Aeroquip 5600 stainless steel ISO 7241-1 series A interchange

- Danfoss Aeroquip FD15 series oil sampling valve

- Danfoss Aeroquip FD17 series high pressure couplings

- Danfoss Aeroquip FD35 series 10,000 psi (hydraulic) couplings

- Danfoss Aeroquip FD45 series self-sealing couplings

- Danfoss Aeroquip FD83 series full flow dual interlock couplings

- Danfoss Aeroquip FD85 series thread to connect

-

Liquid Cooling hose & couplings

- Danfoss Hansen couplings for liquid cooling - data centres

- Danfoss Hansen FD83 series full flow dual interlock couplings

- Danfoss Hansen UQD series liquid cooling couplings

- Danfoss Hansen UQDB series liquid cooling couplings

- Danfoss Hansen BMQC- Blind Mate Quick Connector

- Danfoss Boston Royal EHW194 liquid cooling hose

-

Hansen Couplings

- Gromelle Quick Release Couplings

-

Gromelle Quick-Release Hose Couplings

- Gromelle H5000 series self-sealing couplings

- Gromelle W6000 series screw-to-connect self-sealing couplings

- Gromelle R4000 series non-return valves (in-line check valves)

- Gromelle L7000 series straight through couplings

- Gromelle Safeline ISO 6150B GD10500D series couplings

- Gromelle H15000 series self-sealing couplings

-

Gromelle Quick-Release Hose Couplings

- Danfoss Liquid Cooling Hose & Couplings

-

Liquid Cooling Hose & Couplings

- Danfoss Hansen couplings for liquid cooling – data centres

- Danfoss Hansen FD83 series full flow dual interlock couplings

- Danfoss Hansen UQD series liquid cooling couplings

- Danfoss Hansen UQDB series liquid cooling couplings

- Danfoss Hansen BMQC- Blind Mate Quick Connector

- Danfoss Boston Royal EHW194 liquid cooling hose

-

Liquid Cooling Hose & Couplings

- Mann Tek & Todo Dry-break Fluid Transfer Couplings

- Wash Down Equipment & Hose Reels

Downloads

Details

Corrugated tube allows tight, kink-free bends

Working temperatures between -200°C and +600°C

- Wide temperature range - between -200°C and +600°C

- Fire and damage resistance - tough, all-metal construction

- Long service life - without the ageing deterioration of non-metal hoses

- Excellent steam resistance - longer life than non-metal hoses

- Sizes - from 1/4" up to 4" nb. Larger sizes are available on request

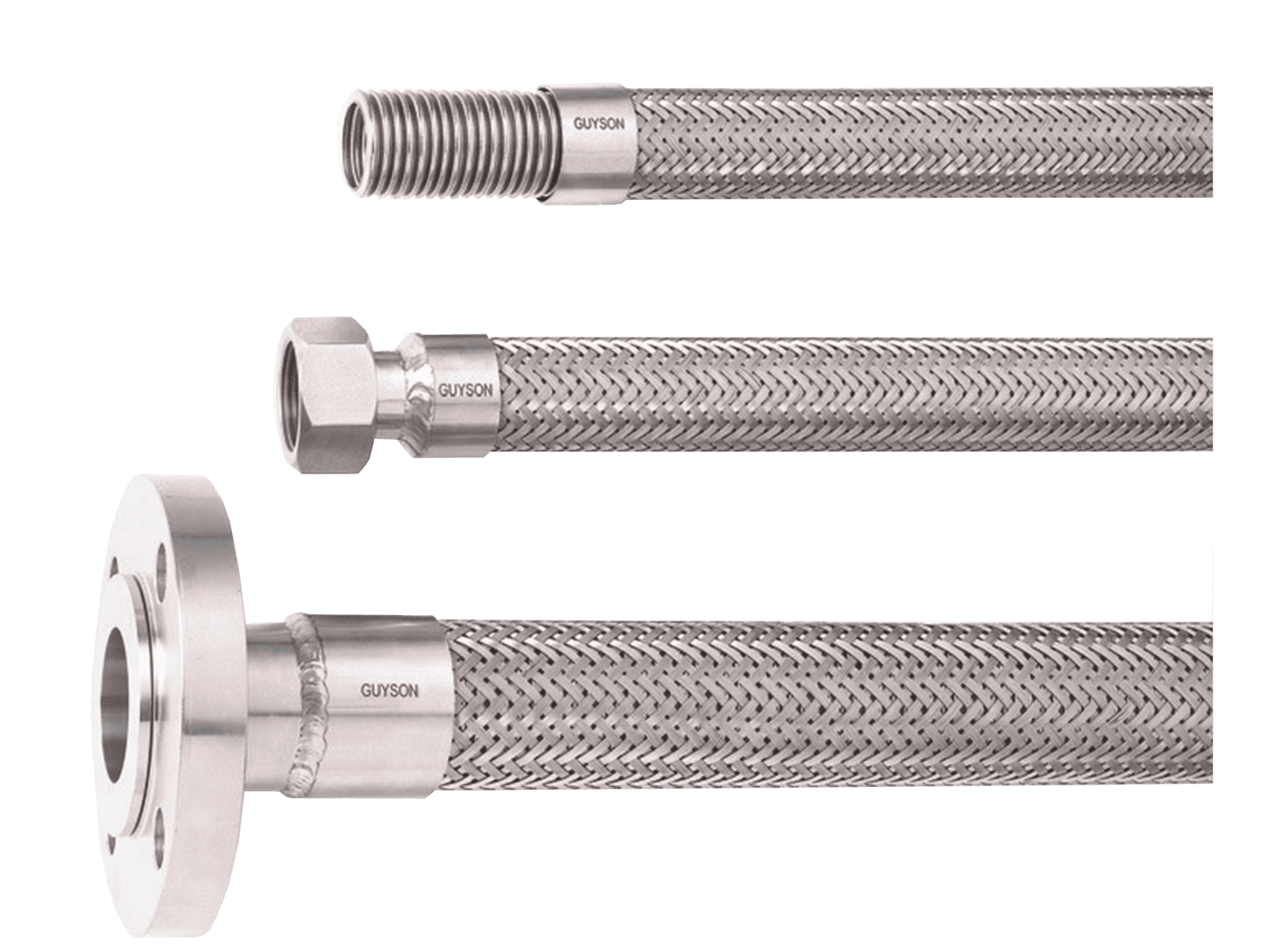

- Wide range of end fittings - BSP, NPT, flanges, hygienic type, specials, etc.

- Applications include: cooling water, steam, oil, hot oil, various gases and vacuum etc. For specific applications and working conditions, please consult Guyson Technical Sales Department.

Most of our Kaptech flexible hose assemblies can be supplied complete with easy to use quick-release couplings: see our Hansen couplings range for details.

Construction:

The Kaptech Stainless Steel flexible hose assemblies listed are manufactured from annularly corrugated tube formed from butt-welded rigid tube, to BS6501 Part 1 type B flexibility; they also meet ISO 10380 class 1. Assemblies to type C flexibility are also freely available.

Single or double layers of wire braid are applied externally to the hose and welded to the fittings at each end to give pressure

holding capability and protection from abrasion. The extent of braiding, gauge and angle of lay is carefully calculated for optimum performance.

The stainless corrugated tube is available in 321 and 316 grade, with braid in 304 or 316; other materials such asbronze, Monel, etc., are also readily available.

End Fittings:

Because Kaptech hose assemblies are individually made in our works they can have end fittings selected to suit customers' application requirements from a wide range of standard and special configurations, including male & female BSP and NPT threads, fixed & swivel flanges to various specifications, hygienic fittings, tube ends, weld ends, quick-release couplings, etc.

Design & Installation: Kaptech Stainless Steel flexibles should be configured and installed in such a way that the minimum bend radius is not exceeded, the hose is not stretched, compressed nor twisted, and the external braid is not subject to wear nor damage.

The use of elbow ends can often help in achieving a satisfactory installation.

Optional Additional Features

Internal Liners - to protect tube against abrasion or high flow velocities.

External Casing - for protection against undue risk of overbending and external damage.

Rubber and Plastic Covers - to give anti-scuff and environmental protection, comfortable handling, and a wipe-clean surface.

External insulation - to maintain fluid temperature and protect operator.

Duplex Assemblies - hose-within-a-hose for heat tracing or cooling.

| Hose Type |

Stainless Steel Hose |

|---|---|

| Bore Size (Inches) |

Sizes from 1/4" up to 4" nb |

| Applications |

Cooling Water ,Steam ,Oil ,Various Gases |

Features & Benefits

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Mauris eros dolor pellentesque sed luctus dapibus lobortis orci.

Feature 1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi volutpat justo sed efficit cursus. Mauris fringilla quam.

Feature 2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi volutpat justo sed efficit cursus. Mauris fringilla quam.

Feature 3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi volutpat justo sed efficit cursus. Mauris fringilla quam.

Feature 4

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi volutpat justo sed efficit cursus. Mauris fringilla quam.

Gallery