- Flexible Hose Assemblies

- Hansen Quick-Release Couplings

-

Hansen Couplings

- Hansen HK series self-sealing couplings

- Hansen ST series straight-through couplings

- Hansen MLDB series dry-break couplings for fluid transfer (stainless steel)

- Hansen ADB series dry-break couplings for fluid transfer (aluminium)

- Hansen MLFF series ISO 16028 dry-break couplings (stainless steel)

- Hansen FF series ISO 16028 dry-break couplings

-

Danfoss Aeroquip

- Danfoss Aeroquip 5400 series low air inclusion refrigerant couplings

- Danfoss Aeroquip 5600 stainless steel ISO 7241-1 series A interchange

- Danfoss Aeroquip FD15 series oil sampling valve

- Danfoss Aeroquip FD17 series high pressure couplings

- Danfoss Aeroquip FD35 series 10,000 psi (hydraulic) couplings

- Danfoss Aeroquip FD45 series self-sealing couplings

- Danfoss Aeroquip FD83 series full flow dual interlock couplings

- Danfoss Aeroquip FD85 series thread to connect

-

Liquid Cooling hose & couplings

- Danfoss Hansen couplings for liquid cooling - data centres

- Danfoss Hansen FD83 series full flow dual interlock couplings

- Danfoss Hansen UQD series liquid cooling couplings

- Danfoss Hansen UQDB series liquid cooling couplings

- Danfoss Hansen BMQC- Blind Mate Quick Connector

- Danfoss Boston Royal EHW194 liquid cooling hose

-

Hansen Couplings

- Gromelle Quick Release Couplings

-

Gromelle Quick-Release Hose Couplings

- Gromelle H5000 series self-sealing couplings

- Gromelle W6000 series screw-to-connect self-sealing couplings

- Gromelle R4000 series non-return valves (in-line check valves)

- Gromelle L7000 series straight through couplings

- Gromelle Safeline ISO 6150B GD10500D series couplings

- Gromelle H15000 series self-sealing couplings

-

Gromelle Quick-Release Hose Couplings

- Danfoss Liquid Cooling Hose & Couplings

-

Liquid Cooling Hose & Couplings

- Danfoss Hansen couplings for liquid cooling – data centres

- Danfoss Hansen FD83 series full flow dual interlock couplings

- Danfoss Hansen UQD series liquid cooling couplings

- Danfoss Hansen UQDB series liquid cooling couplings

- Danfoss Hansen BMQC- Blind Mate Quick Connector

- Danfoss Boston Royal EHW194 liquid cooling hose

-

Liquid Cooling Hose & Couplings

- Mann Tek & Todo Dry-break Fluid Transfer Couplings

- Wash Down Equipment & Hose Reels

Downloads

Details

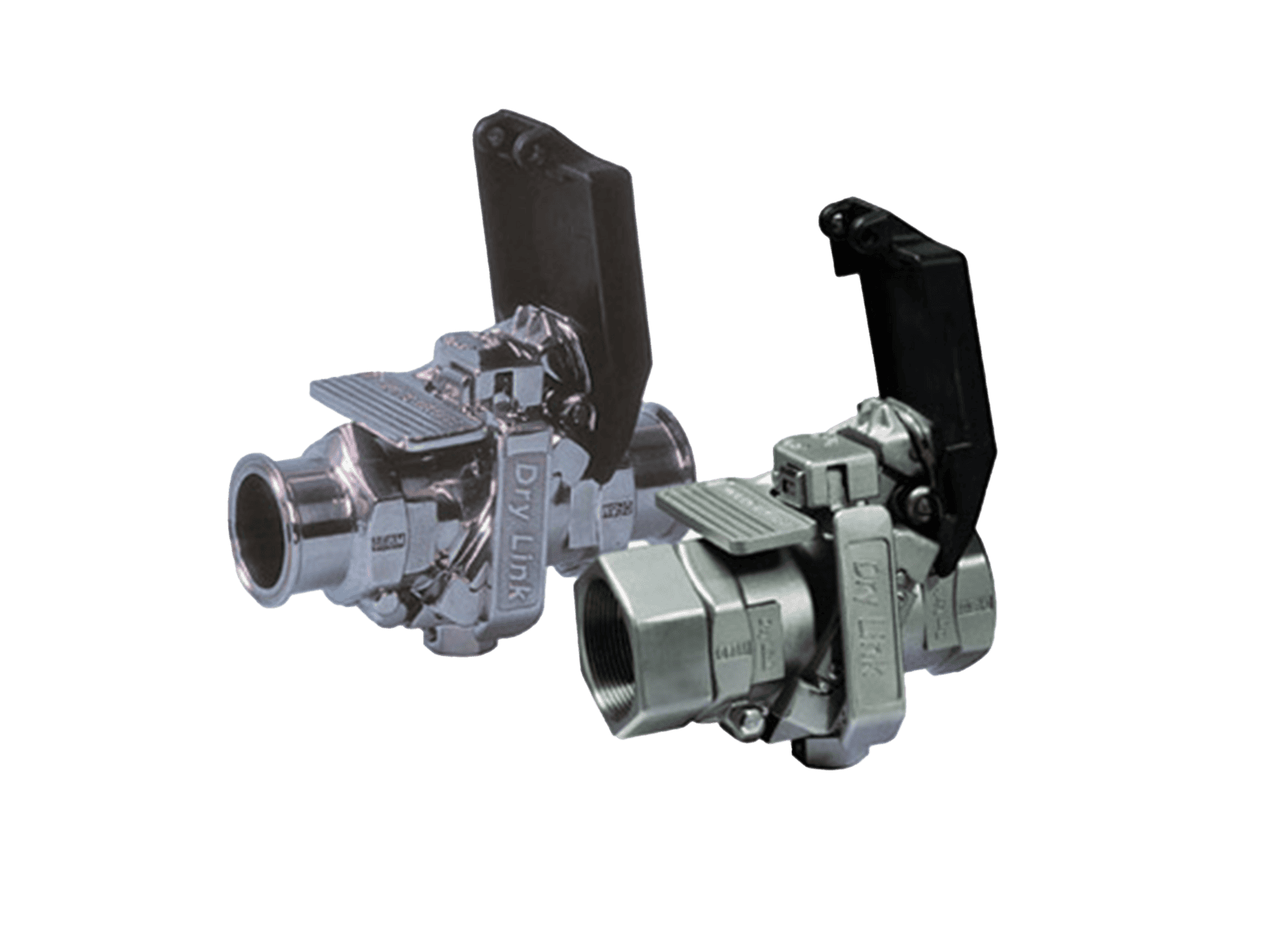

Tamper-proof once installed

Reliable, leak-free operation

Features include

- Spill-free liquids handling

- High flow characteristics

- Sizes 1" - 4"

- Available in stainless steel as standard

- Alloy 20 and Hastelloy C versions available to order

- Unique non-interchange connections

- Keying system for selectivity of lines

Applications include: chemicals, solvents etc. For specific applications and working conditions, please consult Guyson Technical Sales department. Dry-Link couplings can also be supplied as part of a ready-to-use flexible hose assembly: see our Kaptech flexible hose range for details.

| Model |

Dry Link Couplings |

|---|---|

| Materials |

Stainless Steel |

| Applications |

Chemicals ,Solvents |

Features & Benefits

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Mauris eros dolor pellentesque sed luctus dapibus lobortis orci.

Feature 1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi volutpat justo sed efficit cursus. Mauris fringilla quam.

Feature 2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi volutpat justo sed efficit cursus. Mauris fringilla quam.

Feature 3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi volutpat justo sed efficit cursus. Mauris fringilla quam.

Feature 4

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi volutpat justo sed efficit cursus. Mauris fringilla quam.

Gallery